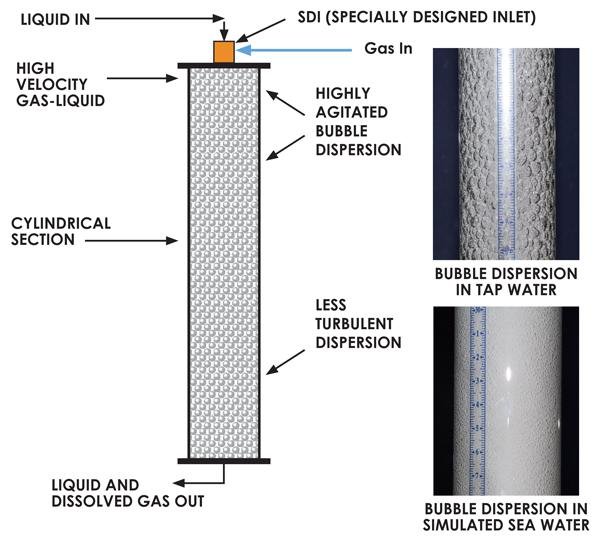

The Downflow Gas Contactor Reactor (DGC) is one of the most efficient gas liquid contacting devices available for the process industries. It has evolved from a novel concept of contacting a continuous liquid phase with a dispersed gas phase through a specially designed entry section.

Under operating conditions large quantities of reaction gas and slurry liquid are introduced via a proprietary reactor inlet to create a well dispersed gas/liquid dispersion of high gas hold-ups and very high gas/liquid mass transfer area (1000 m2/m3 to 6000 m2/m3 depending on bubble sizes). The high gas/liquid ratio throughout the dispersion in the column results in excellent gas-liquid contacting and enables the maximum possible gas-liquid mixing and mass transfer.

The gas/liquid dispersion is maintained at a desired level within the reactor preventing gas bubbles flowing through the outlet of the reactor and thus ensuring 100% gas utilisation.