Gas liquid contacting devices are used widely in the chemical industry for absorbing gases into liquids and solvents. These devices range from stirred vessels to packed beds and bubble columns and are employed for a variety of different industrial applications, including CARBON CAPTURE FROM AIR.

Most applications employ an upflow mode of gas flow with relatively low gas hold-ups (< 20%) along with subsequent gas disengagement with recycling, coalescence and backmixing problems. Free gas liquid interfaces with gas pockets are formed in these reactors causing safety problems. Furthermore downflow bubble columns usually operate with jet entrainment of gas and gas bubbles therefore require subsequent disengagement and uneconomic utilisation of gas whilst the interfacial area is not optimised.

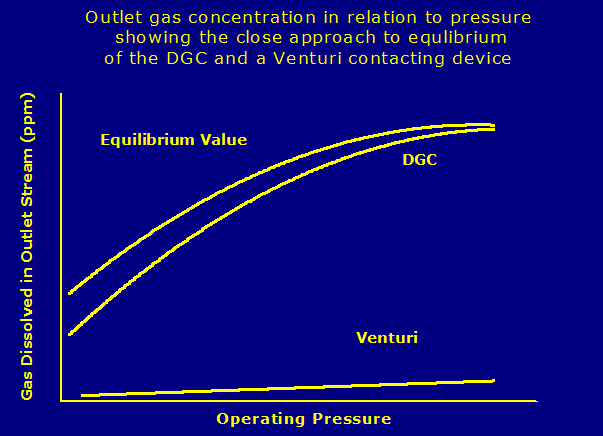

The DGC offers significant advantages over more conventional gas-liquid contacting devices and is able to achieve saturation in very short reaction times. Some of the advantages of the DGC when compared with other contacting devices are highlighted below.

See some graphical comparisons of the Downflow Gas Contactor.