Many industrial applications require some form of chemical reaction as a fundamental stage in the manufacturing process. These reactions are conventionally undertaken in chemical reactors and are often limited by the degree of mass transfer achieved. This is generally caused by insufficient mixing and is particularly true for fast chemical reactions.

Conventional reactors such as stirred vessels, packed bed and bubble columns are widely employed in the process industries and often encounter problems such as low gas hold-ups (< 20%), gas disengagement, inefficient mixing, coalescence and backmixing.

The Downflow Gas Contactor (DGC) has been successfully used as a three phase chemical reactor for a number of different industrial applications. The results have shown that the DGC is a very efficient gas-liquid-solid contacting device providing a high degree of mass transfer with chemical reaction that is almost entirely reaction rate controlled.

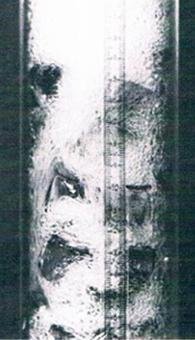

The DGC can be operated as a slurry reactor and also in a packed bed form with catalyst monoliths or packings.

Due to the intense level of mixing achieved in the DGC, all reactions are completed in much shorter reaction times and with better selectivity and higher yields.

The DGC reactor has many advantages over more conventional devices. See the Advantages page for further information.

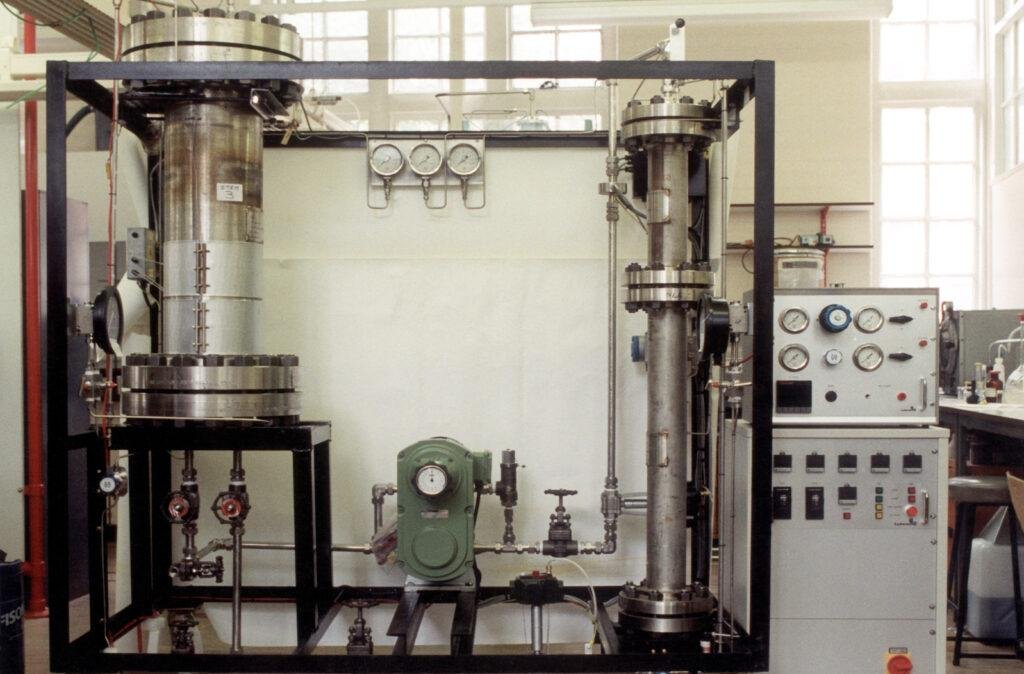

Elevated ‘Pressure and Temperature’ DGC Reactor

Packed Bed DGC Reactor

Hydrogenation Reaction